About Technical Metal

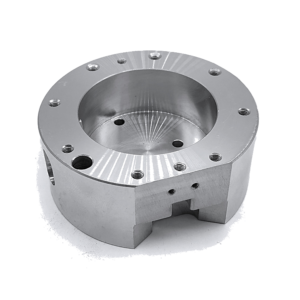

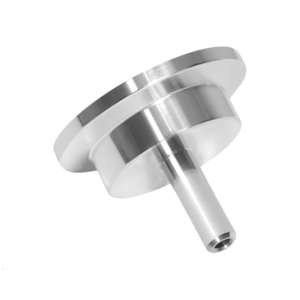

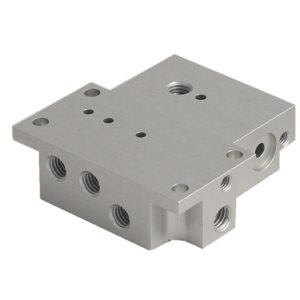

JSK Industrial Supply offers a wide range of advanced technical metal materials including sheets, tubes, square bars, rods, and finished custom components. For metal products we have extensive grinding, turning, milling, and cutting capability to provide polishing, lapping, metalizing, brazing, and joining upon request. We are happy to produce any quantity of items – from one-off prototypes up to large production runs, we have the capability to meet our customers’ diverse requirements. We typically reply to quotes for custom technical ceramic parts within 24 hours (depending on the complexity) and have our materials in stock to ensure quick product turn-around

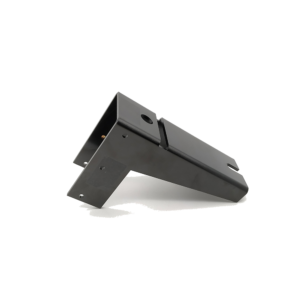

JSK Industrial Supply has an experience needed to deliver full metal fabrication services for our customers on time and on budget. As your first choice for fabrication, stamping, deep drawing, tube fabrication, welding or machining, we will work with you to ensure top quality and “on-time delivery” by utilizing our extensive expertise.

Standard Parts

Materials

Process Capability

Our capabilities are constantly evolving through our staff training and new partners. We have the experience and capabilities required to meet the custom metal parts and assemblies needs of large and small customers alike. We provide design and manufacturing engineering support, outstanding customer service, consistent product quality, and on-time delivery. We work with a range of materials including cold and hot rolled steel, spring steel, stainless steel, aluminum, copper, and brass, all of these in forms such as coil, sheet, bar stock, tubing, and plate. One of our advantage capabilities is that we are very strong in designing jigs and fixtures for our process control. As a standard practice, we always use customized jigs and fixtures to hold, locate, and guide the products in all our manufacturing processes. This will ensure the maximum quantity of production and adhering to the specified or better quality standards for customers.

At JSK Industrial Supply, we aim to handle all fabrication jobs in the most professional and flawless manner possible. This allows our customers the freedom to focus on their core competencies, fostering customer growth without the restriction of manufacturing constraints and large capital investment. You can count on us to deliver metal products when you need them and how you need them.

Heat Treatment

Finishing Services From Certified Suppliers

JSK Industrial Supply’s world-class network of finishing suppliers is at your fingertips, saving you time and money trying to find the right one for your project.

Adhesives

- Black Oxide

- Powder Coat

- Wet Paint

Anodizing

- Type II Anodize

- Type III Hard coat

- Type III w/ PTFE

Part Marking

- Ink Stamping

- Laser Marking

- Silk Screening

Surface Treatment

- Bead Blasting

- Electropolishing

- Etching

Metal Plating

- Copper Plating

- Electroless Nickel

- Electrolytic Nickel

- Nickel Plating

- Tin

- Zinc

Conversion and Pre-treatments

- Chem Film

- Chromate Conversion Coating

- Heat Treat

- Passivation

- Pickle and Oil

Heat Treatment

- Annealing

- Carburizing

- Cryogenic Treatment

- Flame Hardening

- Hydrogen Embrittlement Relief

- Induction Hardening

- Stress Relieving