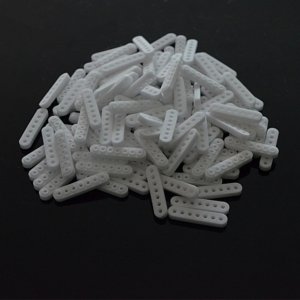

Description

Ceramic Custom part

Zirconia ( ZrO2 substrate )

Compared to alumina substrate, ZrO2 substrate has higher mechanical strength and fracture toughness it’s about three times higher for bending strength, two times for fracture toughness than alumina substrate. ZrO2( zirconia ) also provides good abrasion

resistance. It features a thermal expansion rate close to metals.

Aluminium Nitride ( AlN substrate )

Aluminium Nitride has higher thermal conductivity, compared to alumina substrate. It is about 7 to 8 times high. AlN substrate is an excellent electronic package material.

beryllium oxide ( BEO substrate )

Beryllium oxide (BEO) ceramic material are in high demand due to their superior performance at high temperatures along with a thermal conductivity second only to diamond among insulating materials.

Material : 96% Alumina Ceramic Substrates/Ceramic Plate Thickness: 0.38-0.5-0.635-0.8-1mm of the ceramic substrate.

FAQ

1. who are we?

We are based in GUJARAT, India, start from 2018,sell to Northern Europe(20.00%),North America(20.00%),Domestic Market(10.00%),South America(5.00%),South Asia(5.00%),Southern Europe(5.00%),Central America(5.00%),Western Europe(5.00%),Eastern Asia(5.00%),Mid East(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Ceramic parts,Metal parts,Plastic parts,Custom parts,Upcasting parts

4. why should you buy from us not from other suppliers?

With 15+ Years of Experience JSK Industrial Supply provides businesses with custom-made industrial Ceramic, Plastic & Metal Parts.

Our team can help you to convert your idea from the concept to design, prototype, sample production, and mass production.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,Japanese,Korean,Hindi