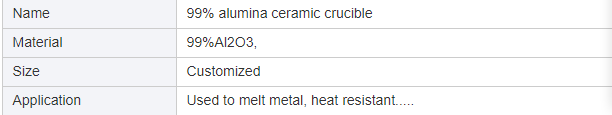

Description

Alumina Ceramic Crucible

Clay Crucible—Assay Crucible It is mainly used in the analysis of metal samples and melting samples in laboratories, mineral laboratories and various industrial laboratories. The samples and ingredients are put into the crucible, and the melting experiment is carried out at high temperature. The lead button obtained by liquid precipitation is then subjected to the next experiment; Features: High refractoriness, no slag, no penetration, no cracking, it is the first-class auxiliary equipment for fire assay. Customized sizes and services are available.

Manufacturing Options

* Injection molding

* Roll compacting

* Co-firing

* Isostatic pressing

* Dry pressing

* Hot pressing

* Tape casting

* Slip casting

Advanced Finishing Services

* Precision grinding and lapping

* Laser machining

* Engineering design and support

* Metallizing

* Metal brazing

* Specialized coatings

* Threaded components

* Precision motion components

* Complex cleanroom assemblies

Production Process

1. There are two types of forming methods for clay crucibles: roll forming and stamping forming.

2. Physical and chemical indexes of clay crucible: refractory temperature 1580℃, alumina content: between 40% and 45% 3. Features: High refractoriness, no slagging, no penetration, no cracking, it is the first-class auxiliary consumable for fire Assay. All raw materials are ball milled, blended, and filtered in proportion. Put the practiced mud in a mud press, press it into a circle, and cut. Customize corresponding molds according to different size specifications Put the cut mud into the mold and rotate it at high speed to form a blank. Place the formed crucible on a drying cart to dry, and put it in a high-temperature kiln for 11 hours.

4.Wrap up and store.

FAQ

1. who are we?

We are based in GUJARAT, India, start from 2018,sell to Northern Europe(20.00%),North America(20.00%),Domestic Market(10.00%),South America(5.00%),South Asia(5.00%),Southern Europe(5.00%),Central America(5.00%),Western Europe(5.00%),Eastern Asia(5.00%),Mid East(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Ceramic parts,Metal parts,Plastic parts,Custom parts,Upcasting parts

4. why should you buy from us not from other suppliers?

With 15+ Years of Experience JSK Industrial Supply provides businesses with custom-made industrial Ceramic, Plastic & Metal Parts.

Our team can help you to convert your idea from the concept to design, prototype, sample production, and mass production.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,Japanese,Korean,Hindi