About Boron Nitride

Boron Nitride is an advanced synthetic ceramic material available in solid and powder form. Its unique properties – from high heat capacity and outstanding thermal conductivity to easy machinability, lubricity, low dielectric constant and superior dielectric strength – make boron nitride a truly outstanding material.

In its solid form, boron nitride is often referred to as “white graphite” because it has a microstructure similar to that of graphite. However, unlike graphite, boron nitride is an excellent electrical insulator that has a higher oxidation temperature. It offers high thermal conductivity and good thermal shock resistance and can be easily machined to close tolerances in virtually any shape. After machining, it is ready for use without additional heat treating or firing operations.

In inert and reducing atmospheres, the AX05 grade of Boron Nitride grades will withstand temperatures over 2,000°C. It is commonly used as an insulator in contact with tungsten and graphite electrodes at those temperatures.

All Boron Nitride grades can be used in oxidizing atmospheres up to 750°C. It is not wet by most molten metals and slags and can be used in contact with most molten metals including aluminum, sodium, lithium, silicon, boron, tin, germanium, and copper.

Boron Nitride is available in a variety of solid grades, differentiated by binder and composite – A, AX05, HP, HPL, M, M26 and ZSBN.

We Supply

Rods, Bars & Roller

Plate & Disk

Industrial Powders

To make solid shapes, hBN powders and binders are hot-pressed in billets up to 490mm x 490mm x 410mm at pressures up to 2000 psi and temperatures up to 2000°C. This process forms a material that is dense and easily machined and ready to use. It is available in virtually any custom shape that can be machined and has unique characteristics and physical properties which make it valuable for solving tough problems in a wide range of industrial applications.

- Excellent thermal shock resistance

- High electrical resistivity – excluding aerosols, paints, and ZSBN

- Low density

- High thermal conductivity

- Anisotropic (thermal conductance is different in different planes relative to pressing direction)

- Corrosion resistant

- Good chemical inertness

- High temperature material

- Non-wetting

- High dielectric breakdown strength, >40 KV/mm

- Low dielectric constant, k=4

- Excellent machinability

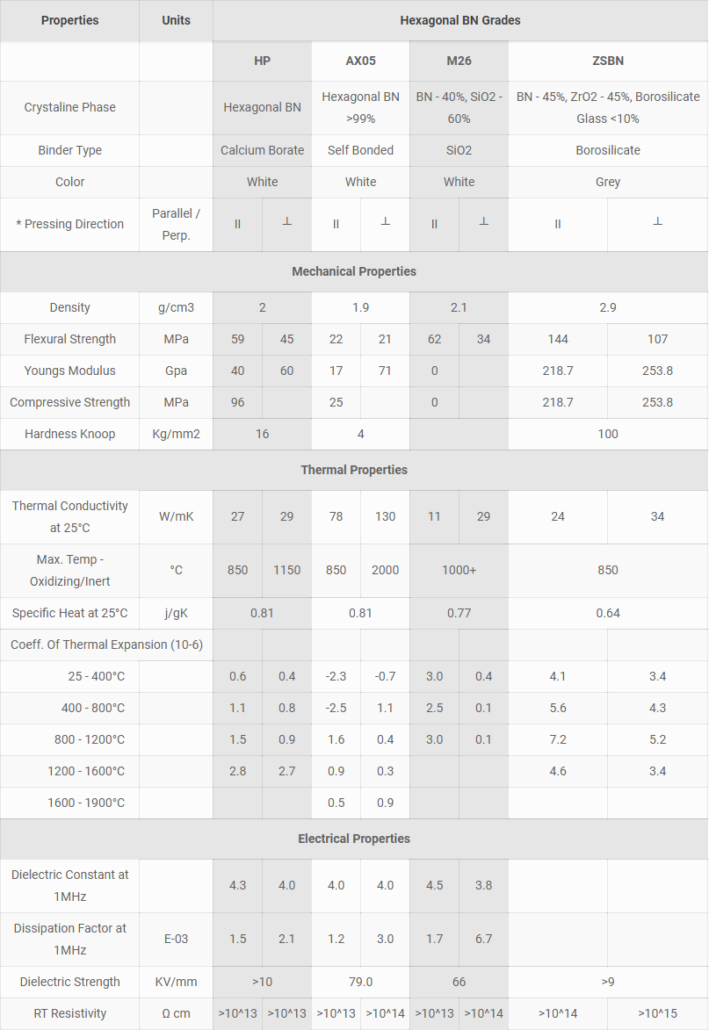

Technical Boron Nitride Properties

* Note – When solid boron nitride is hot pressed, the crystal structure of the material orients itself. This results in anisotropic physical and thermal properties; meaning they vary depending on the orientation of the material relative to hot pressing direction (parallel or perpendicular).

Boron Nitride Applications

- Break rings for continuous casting of metals

- Break rings for continuous casting of metals

- Heat treatment fixtures

- High temperature lubricant

- Molds/mold release agent

- Molten metals and glass casting

- Nozzles for transfer or atomization

- Laser nozzles

- Nuclear shielding

- Induction heating coil supports

- Spacers

- High-temperature & high-voltage electrical insulators

- Furnace supports which require electrical resistivity

- Crucibles and containers for high purity molten metals

- Radar components and antenna windows

- Ion thruster discharge channels

Boron Nitride for Thermal Management of Electronic Devices

Boron Nitride is one of the few materials that offers electrical insulation and high thermal conductivity. This makes BN extremely useful in high power electronic applications in heat sink and heat spreader applications. Other materials that are commonly used are Aluminum Nitride, beryllium oxide, and sometimes Alumina – however, all of these materials are significantly more difficult to machine into intricate shapes.

Boron Nitride Machining

Hexagonal boron nitride can be machined into highly complex geometries with very tight tolerances. Precision Ceramics has 3, 4 and 5 axis CNC machining capabilities and over 20 years of experience creating custom boron nitride components.

Buy Hexagonal Boron Nitride

JSK Industrial Supply is your Alumina machining specialist for your technical ceramic prototyping & manufacturing needs; we are always happy to use our many years of advanced ceramics experience to provide advice on materials, design, and application. If you would like to buy Alumina plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.