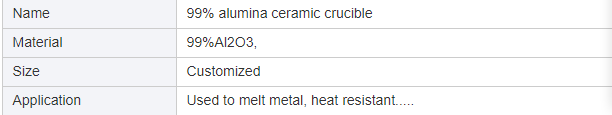

Description

Alumina Ceramic Crucible

Specifications from the graphite crucible :

1.Long working lifetime: its working lifetime is increased 3-5 times over normal clay-crucible due to the compact body formed under high pressure.

2.High thermal conductivity: high-density body and low apparent porosity greatly improve its heat conductivity.

3.New-style materials: new heat conduction material ensures faster heat conductivity and pollution-free product, reduces adherent slag.

4.Resistance to corrosion:better anti-corrosion than normal clay-crucible.

5.Resistance to oxidation: advanced process dramatically improves its oxidation resistance, which ensures persistent heat

conductivity and long working lifetime.

6.High-strength: high-density body and logical structure make the product better compression property.

7.Eco-friendly: energy-efficient and pollution-free, not only ensure metal product purity, but also ensure sustainable development on environment.

NOTICE: We also supply Copper-melting Clay Graphite Crucible and Aluminum-melting Clay Graphite Crucible. Meanwhile, a matched graphite stand is strongly recommended in order to expand the lifetime and improve heat conduction of crucible.

The crucible is an utensil or melting tank vessels that is made of refractory material (such as clay, graphite, clay, quartz or difficult molten metal iron, etc.).

Graphite crucible, which is divided into general type of graphite crucible, special type of graphite crucible, high purity

graphite crucible.Graphite crucible, which is divided into general type of graphite crucible, special type of graphite crucible, high purity graphite crucible.

The main raw materials of Graphite crucible is natural crystalline graphite. Therefore, it maintains the original natural graphite various physical and chemical properties.

Graphite crucible has good thermal conductivity and high temperature resistance;Uder the high temperature, the thermal expansion coefficient is small, rapid heating, quench with certain anti-strain properties. The strong corrosion resistance of acid, alkaline solution has excellent chemical stability.

Graphite crucible, with their more excellent performance, in metallurgy, casting,mechanical, chemical and other industrial sectors, is widely used in smelting and alloy tool steel smelting of non-ferrous metals and their alloys . Besides,it has achieved a good technical and economic results.

Manufacturing Options

* Injection molding

* Roll compacting

* Co-firing

* Isostatic pressing

* Dry pressing

* Hot pressing

* Tape casting

* Slip casting

Advanced Finishing Services

* Precision grinding and lapping

* Laser machining

* Engineering design and support

* Metallizing

* Metal brazing

* Specialized coatings

* Threaded components

* Precision motion components

* Complex cleanroom assemblies

FAQ

1. who are we?

We are based in GUJARAT, India, start from 2018,sell to Northern Europe(20.00%),North America(20.00%),Domestic Market(10.00%),South America(5.00%),South Asia(5.00%),Southern Europe(5.00%),Central America(5.00%),Western Europe(5.00%),Eastern Asia(5.00%),Mid East(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Ceramic parts,Metal parts,Plastic parts,Custom parts,Upcasting parts

4. why should you buy from us not from other suppliers?

With 15+ Years of Experience JSK Industrial Supply provides businesses with custom-made industrial Ceramic, Plastic & Metal Parts.

Our team can help you to convert your idea from the concept to design, prototype, sample production, and mass production.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,Express Delivery;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,Japanese,Korean,Hindi